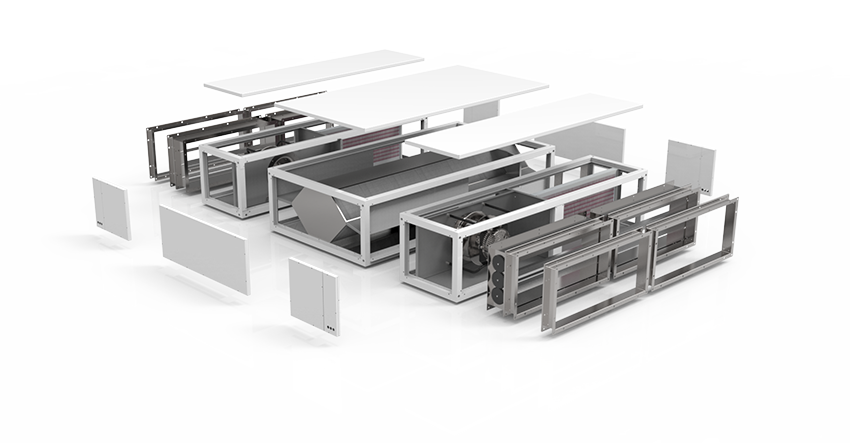

WK-com F air handling units with flat construction

High performance, compact design

Always the right decision!

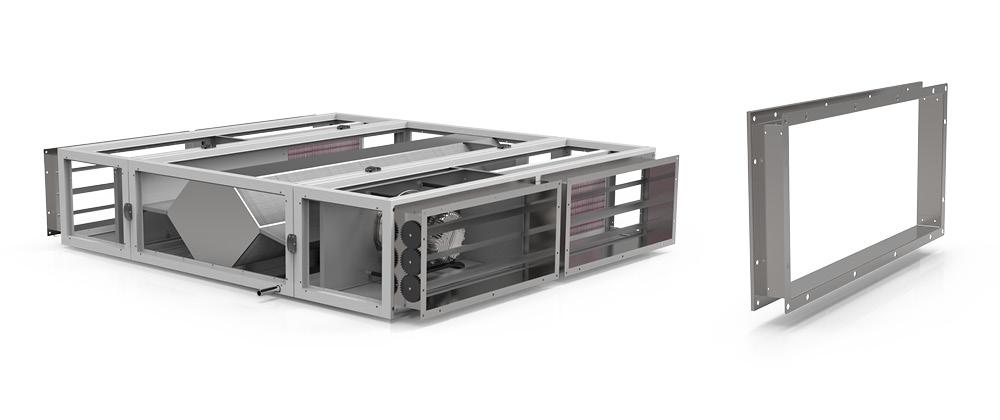

WOLF-Kompakt-Flachbaugeräte WK-com F sind für die komfortable und effiziente Be- und Entlüftung anspruchsvoller Aufgabenstellungen bestens geeignet. Die kompakten Ausführungen der energetisch optimierten Module sind vielseitig einsetzbar und verfügen über einen hohen Leistungsbereich. Die Wartung erfolgt komfortabel nach Kundenwunsch von unten oder seitlich am Gerät. Die komplette Innenverkabelung aller Komponenten auf die individuell konfigurierbare Regeleinheit WOLF C-max bzw. auf die Klemmeinheit (bei Verwendung einer bauseitigen Regelung) ermöglicht einen vielseitigen und maßgeschneiderten Einsatz.

Your benefits

- Units can be operated and serviced from the side or from below

- Compact design that complies with all standards and regulations

- Large output range of up to 3500 m3/h

- Designed to VDI 6022

- Compliance with Ecodesign Regulation 2018

- Efficient, high-grade and performance-tested fitted parts

- Acoustically optimised casing design for nearly silent operation

- Easy installation thanks to stable self-supporting casing design

- Prepared for suspended mounting as standard

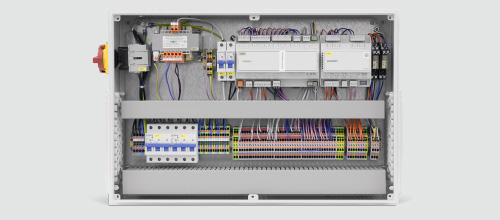

- All internal cabling on externally mounted switch cabinet/terminal unit

- Optional switch cabinet with WOLF C-max DDC controller mounted or supplied loose for wall mounting

- Large selection of control devices, room programming units and touch panels

- Communication possible via Modbus, BACnet and LON

- Individually expandable with demand-optimised components, such as silencers, heating coils (PWW/electrical), cooling coils (PCW/direct expansion coil), filters and many more.

- Casing in zinc-plated sheet steel, stainless steel V2A, aluminium AlMg3, paint finish (RAL to customer requirements)

- Versatile application

- Calculation with tested and certified sizing program

Quality guarantee

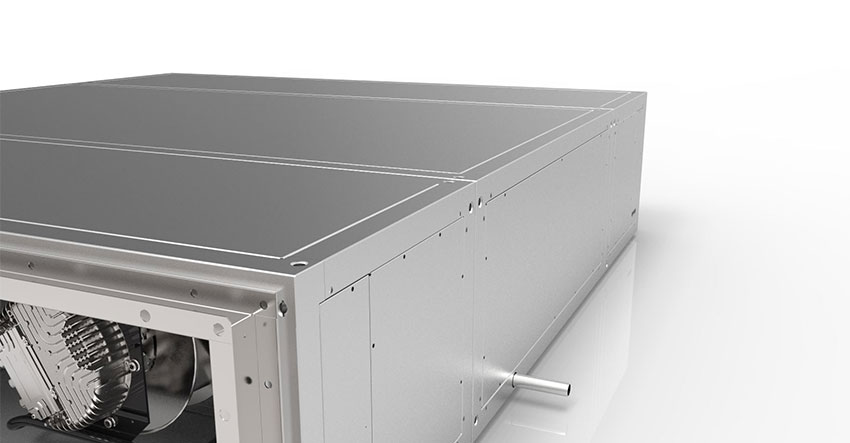

The compact solution

WK-com F air handling units are the ideal solution for providing rooms with optimum air conditioning from compactly sized units. The extremely slimline units of this series feature superior energy efficiency, power saving EC fans, efficient heat recovery systems and tested filter technology. The perfect system for your air handling requirements. With our modular system, there are no limits to your adaptation options. They air condition your project in line with demand, hygienically to VDI 6022 and efficiently to ErP 2018.

WK-com F außen

Control

Optionally without control unit, with internal wiring to externally mounted docking stations and terminal boxes.

Material variety

Unit mounting

Hygiene

Noise transmission

Unit mounting

The standard unit mounting holes and optional mounting brackets enable simple and secure ceiling mounting with the on-site decoupling elements and suspensions. Access for inspection and maintenance is not impaired.

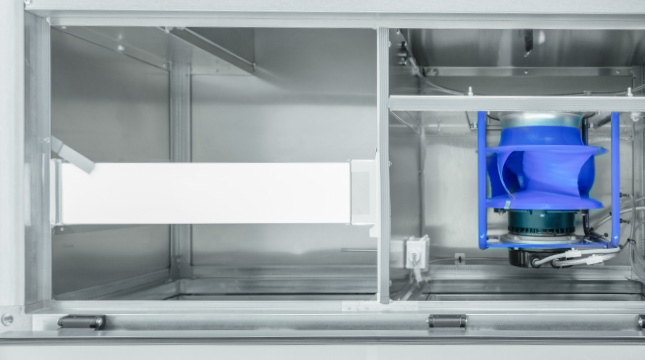

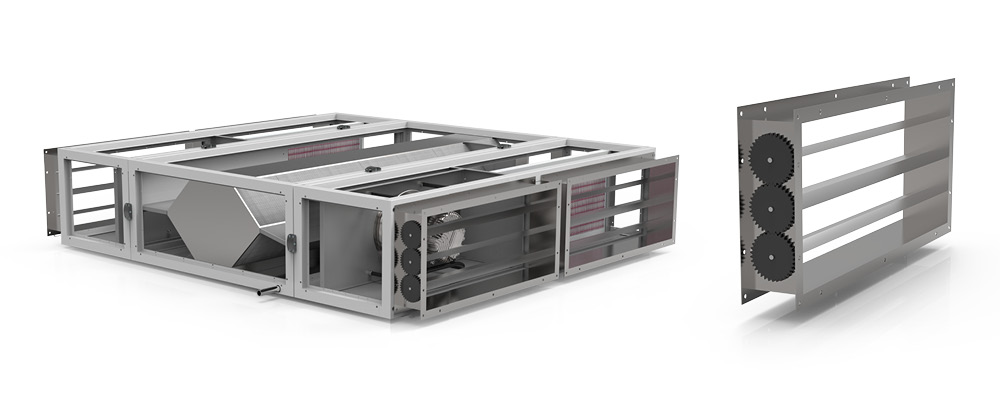

WK-com F interior

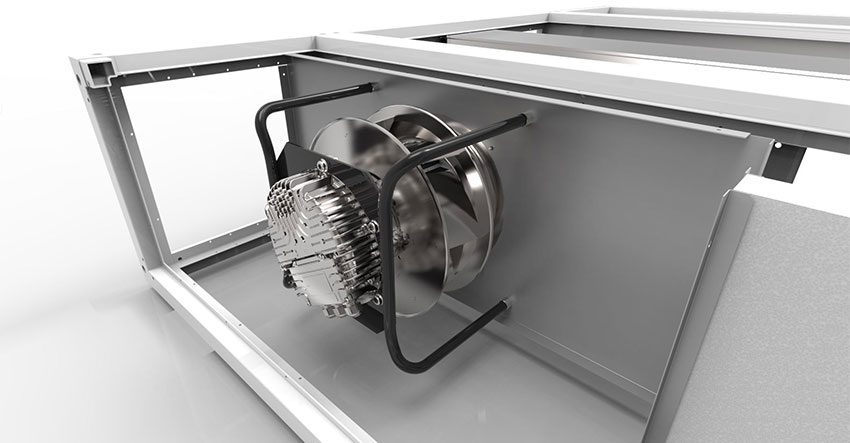

Fans

The integrated electronics make frequency converters unnecessary and ensure demand-dependent, variable speed control.

3D Condensate Pan

Heat recovery

Filters

Options, combination and extension modules

Fan module

Various individually sized and optimised EC fans can be used for each unit size. With their integrated electronics, the fan/motor units allow continuously variable output control.

The sizing takes account of all external and internal resistances and ensures that the optimum fan is always selected.

Fan module

The frame is available in zinc-plated and stainless steel 1.4301 versions, whilst the cladding panels can be supplied zinc-plated, in aluminium AlMg3, stainless steel 1.4301 or with a RAL paint finish according to customer specification.

Louvre dampers

Tightly closing aluminium louvre dampers (tightness category 2 to EN 1751) with external gears and axle for servomotor connection.

Unit connection

Units are connected exclusively with solid insulating connectors made from zinc-plated sheet steel (optionally stainless steel) with an integral insulating element for structure-borne noise separation. This largely prevents transmission of acoustic and structure-borne noise.

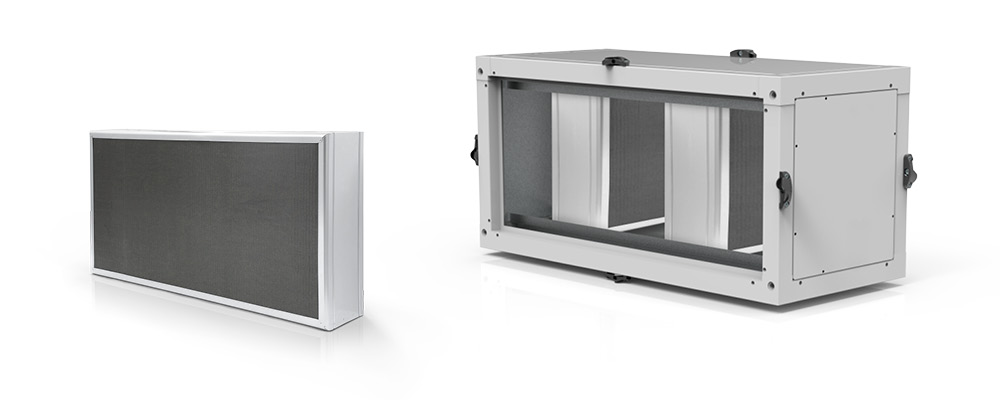

Filter module

The integrated panel filters with a very large filter surface area of grade M5-F9 (to EN 770 / grade ePM10 to ISO 16890) have an installed depth of 48 and 96 mm.

Bag filters, compact filters, activated charcoal filters, HEPA filters or expanded metal filters can optionally be installed.

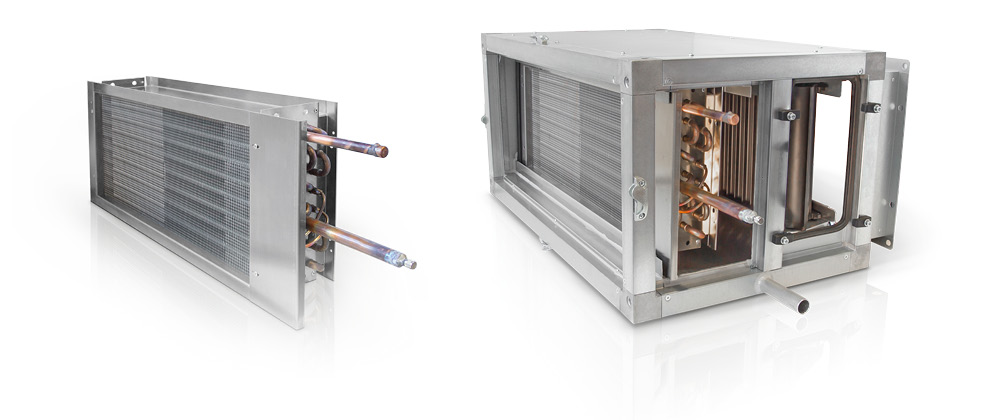

PWW heater module

High-grade casing module equipped with a removable heat exchanger sized individually to the output and made from copper pipes with press-fitted aluminium fins.

Optional: Stainless steel coil frame, Coated fins

Silencer module

High-grade casing module with integral silencer links and glass fibre cover to VDI 6022. The module is sized individually in accordance with the required insertion attenuation.

Electric heater module

High-grade casing module with removable electric heat exchanger individually adjustable to the required output and fitted with integral safety equipment. Connection, output and safety equipment compactly mounted on the module exterior.

PCW cooling module / direct expansion coil

High-grade casing module with integrated aluminium condensate pan with a three-sided slope (to VDI 6022) towards the side condensate drain.

The coil is removable for convenient and thorough maintenance.

The cold water heat exchanger (or direct expansion coil) consists of copper pipes with press-fitted aluminium fins and is sized for the required output.

Optional: Stainless steel coil frame, Coated fins, Removable mist eliminator

»True greatness does not need much space«

Heating and cooling with WOLF inverter heat pumps

A perfectly coordinated system ensures optimum temperatures in summer and winter operation.

- Continuous variable output control 20 – 100 %

- High operational reliability

- Self-sufficient system for heating and cooling operation

- Highly efficient and sustainable due to the use of the refrigerant of the future, R32

- Complete system solution from the manufacturer with continuous efficiency

Regulation WOLF C-max

WOLF C-MAX

Pre-configured for your system

For straightforward commissioning by the customer, the WOLF C-MAX is factory-configured specifically for every customer system. All that remains for the customer to do when commissioning the heat recovery unit is to specify the set values, fixed speeds, flow rate, pressure and switching times.

At a glance

- Room unit on-site control (optional)

- Programming unit (HMI) for commissioning and function extension

- Control unit ready programmed and factory-configured

- User friendly menu system

- Extension modules for BACnet, Modbus,

interface (already programmed, integration of the module into existing BMS on site) - Remote servicing via TCP/IP

- CO2, pressure, constant flow rate control or humidity control are possible

- Software updates by SD card

- Variable 0-100 % via

- 3-stage automatic system

- Constant flow rate

- Constant pressure

- CO2 control

- Humidity control

- Constant supply air

- Extract air/supply air cascade

- Room / supply air cascade