Drying Accessories

Conditioning, Silo, Conveyor Belts

Conditioning

The automatic conditioning plant is adjusting the hops carefully and profitably to the optimal moisture level. The upgrade of the conditioned hops can be seen clearly by its gloss and colour intensity.

By special conveyor belts type BOF, the preprared dried hops are taken to the automatic bagging with press.

These special transport belts are equipped with a multiple side sealing (tub shape) and transport the hops to the press carefully and smoothly.

Silo

The WOLF green hops silo is made of hot-dip galvanized sheet steel and is fed directly from the picking machine. The hops are stored in the silo until they are required in the kiln.

The silo floor is a so-called rolliing floor, consisting of overlapping lamellae making a closed surface. When emptying, the whole floor is moving into dumping direction.

This system prevents the hops from being ground during transport. Especially in combination with WOLF conveyor belts, hop silos are an enormously time-saving investment! With the conveyor belt automatic feeding, the silo is self-monitoring. By automatically feeding the kiln, there are no manual working steps except hanging up the bines at the picking machine.

Conveyor Belts

Dried Hops Conveyor Belt

Type BOF

This conveyor belt has been developed especially for sensitive crops like hops.

New and unique is the WOLF side sealing. The cloth is running in a tub, providing an even transport.

A grinding of the hops by friction is excluded despite high output. Each umbel reaches the kiln without being damaged.

Green Hops Conveyor Belt

Typ N10

This conveyor belt with galvanized cover is designed especially for transporting green hops outside.

The belts (630 mm resp. 770 mm wide) enable an especially fast and careful filling of the kiln.

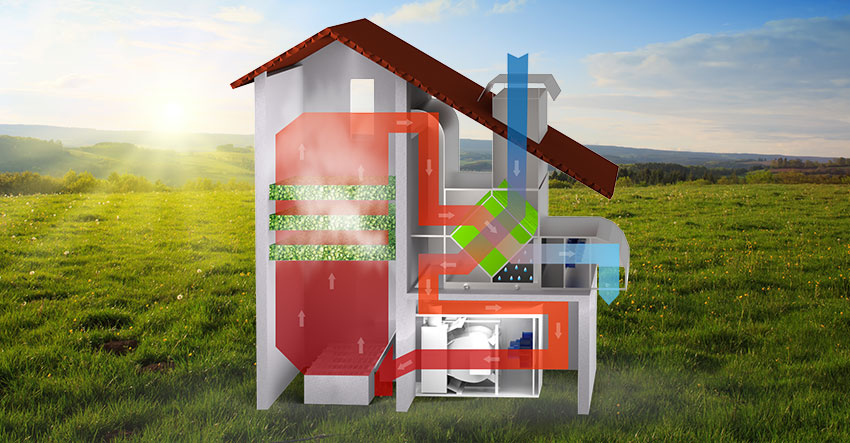

Heat recovery

The WOLF heat recovery system supports an even drying process by active extraction of the moist exhaust air – there is no moisture accumulation in the kiln any more! By modular and flexible frame design of the intrinsically stable WOLF profiles, retrofitting is also easy to do for outdoor use.

When retrofitting, the burner capacity can significantly be reduced, thus reducing consumption! WOLF has got more than 50 years of experience in design and planning of units with heat recovery in the field of air conditioning technology and equips hundreds of units every year.