WORK SPACE ©

WOLF Universal Preparation Bays - as Turnkey Complete Solution

Our ambition is to offer our customers complete solutions.

This is what product line WORK SPACE© represents.

WORK SPACE© includes

- the preparation bay with extraction surface (floor / wall extraction)

- the ventilation and deaeration plant

- the air inlet guidance by an air inlet duct, textile ducts or a filter ceiling

- the workplace lighting

- the roller blinds

- the WOLF© terminal for each working bay

- further options

The essential element of WORK SPACE© is the WOLF© terminal, including not only the necessary electric and pneumatic connec-tions, but also considering the requirements of DGUV Information 209-089 for the safe operation of universal preparation bays.

By controlling the terminal, you can select the requested kind of operation; moreover, all relevant plant conditions are signalized.

The operator is given a completely structured working system.

So you will enjoy working!

In order to be able to design optimal solutions for any demand, the terminal is available in two variants:

WOLF© terminal

The terminal is made in switchboard design, consisting of an electric and a pneumatic part. It includes the electric and pneumatic supply of the workplace as well as the control system with safety interlocks.

The electric part includes

- the main switch

- the control system with the operating panel

- electric connections (400 V / 230 V) for infrared / UV-drying units and for tools (230 V)

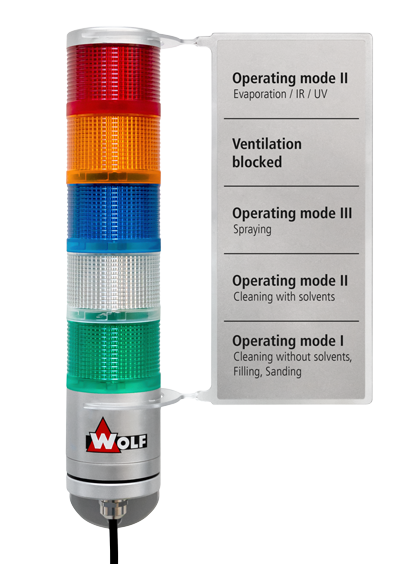

- a mode lamp

The pneumatic part includes

- 1 connection for the spray gun

- 1 connection for universal air (with different coupling to the spray gun)

- the car lift control (if a car lift is included in the scope of supply)

- 1 pressure regulator for spray gun, universal air and car lift, each

- control and safety valves

The terminal is perfectly suited to the connection of a workshop trolley with grinding machines and grinding dust extraction.

WOLF© terminal S

offers the following additional equipment

Equipment for grinding dust extraction

- 1 pressure regulator for the grinding machine

- 1 extraction system with tube reel (10 m) and integrated compressed air tube for the grinding machine

- 1 additional grinding dust extraction connection on the housing

- 1 holder for the grinding machin

Further Equipment

- 1 holder for the spray gun

- 1 compressed air tube (12 m) with tube reel for the spray gun

- 1 compressed air tube (12 m) with tube reel for universal air

- 1 additional 230 V socket with tube reel

Complete Solution with Extraction Turbine

The WOLF terminal S is intended for the connection to an extraction turbine.

We provide complete solutions including connection pipes to the turbine.

Smart & Safe

Everything under control with most modern control technology

Acc. to DGUV Information 209-089, the different activities and processes on universal preparation bays are subdivided into three kinds of operation which in turn are linked with certain requirements regarding air capacity and safety-related interlocks. These requirements are considered in the terminal control system.

With this control system for the first time, the operator has also got the overview of the whole plant. The operator panel of the terminal shows him the current switching state of the central ventilation plant (hall heating / hall ventilation) and informs him if the air capacity for the next working step is sufficient.