REPIT vision Fast-Repair System

Booth Technology without Compromises

Professional Repair Paintwork of Small Damages

REPIT vision systems are one or several energy and process optimized comfort working bays for efficient and fast repair of small damages in spot repair range.

This focuses on „fast repair“– the complete damage repair including top coat.

The difference to open preparation bays where mostly masking, filling, sanding and priming work is done, is the high-end equipment of the REPIT vision working bays.

Benefit from decades of experience in air-conditioning, surface engineering and car repair.

Advantages

- dust-free room concept

- separation of working bays by fixed walls or separating shutters

- front doors or separating shutters

- air inlet ceiling

- standard lighting – for optimal illumination and colour evaluation

- extraction on the wall (wall system) or on the floor (floor system)

- control of working processes spraying / IR-drying / air-conditioning by touch panel

- energy and process optimized programmes

- automatic safety locking technology of IR-beamers and sockets

- additional equipment* like compressed air supplies, sockets etc. (including connection to safety technology)

- room air conditioning – heating-ventilating-cooling* – for comfortable working

Fast Repair with REPIT vision

Due to optimal working bay equipment and flexibility, shortest cycle times are reached. The whole working process from preparing, spraying, drying to finishing is being done on one working bay. This is the most economic solution of small damages repair. The functional, process-reliable and clean design of booth technology enables best working results. The guidelines of Trade Associations with clearly phrased regulations to minimum air capacities and interlockings between application, infrared drying and technical ventilation are monitored.

Thus, for small damages repair, the REPIT vision system is positioning itself between the WOLF universal working bays and the premium spray booth TAIFUNO®vision.

For larger spraying volumes, the TAIFUNO®vision booth remains first choice, which has always been proven by practice. Here, the sentence „Rather moving more than making a quality compromise“ applies.

Difference to Spray Booth

Control System

Ventilating / Drying IR

This kind of operation is selected for cleaning with solvents, for the flash-off phase after application and for IR-drying. The working bay is switched to a reduced fresh/exhaust air capacity (at least 50 % to application). Compressed air supply for application is automatically blocked.

Application

When applying primer and paint, the working bay is switched to fresh/exhaust air operation for the preset time. The minimum air capacity here is 15.000 m³/h. An electric locking secures that spraying is only possible with technical ventilation. Voltage supply for sockets at the working bay is automatically blocked

Air-conditioning

In this kind of operation, the room climate of all working bays or of one single working bay is regulated. When selecting „Ventilating“, all working bays are operated at the same time in fresh/exhaust air operation. The whole air of the ventilating machinery is divided to the working bays. When selecting „heating“, the ventilating machinery is switched to recirculating air operation and all bays are tempered to the adjusted value. „Heating at working bay“ means that only the respective working bay is tempered. As a specialist in air-conditioning, we are of course able to fulfill special wishes, for example an air-conditioning with refrigeration technology.

Further functions

Electrically driven shutters and lighting are also switched by the Touch-Panel.

The control system of the REPIT vision system has been conceived acc. to the following target criteria:

- process safety

- optimal energy management

- working safety

- easy handling

- comfortable room climate

Its model has been the logical and convincing control conception of the TAIFUNO®vision booth.

All process steps are being controlled by the single kinds of operation. Safety is automatically guaranteed in the background.

Housing and Space Disposition

Booth Solution

Die REPIT vision booth with fixed housing of the whole area, manually or automatically driven front doors and lateral separating shutters provides best conditions for avoiding dust ingress from the workshop range to the working bays.

Separating shutters on all sides

As an alternative to the housing, the outside separation of the working bays can also be done by antistatic separating shutters.

Air Inlet Ceiling

TAD - Air Inlet Ceiling

(Textile Air Distribution)

The TAD air distribution system by WOLF is a new air inlet ceiling used for REPIT vision bays. The air inlet ceiling consists of several textile flow ducts whose blow-out openings can exactly be determined depending on room size and requested flow direction, providing a very uniform flow profile in the room. The textile ducts are fixed at a ceiling rail system and can easily be removed for cleaning. For this solution, the air inlet filter is placed in the ventilating machinery.

Filter Ceiling

As an alternative to the TAD-system, a filter ceiling is provided between the lighting. Here, the same filters (filter class M6) as in the spray booth are used.

Extraction

Floor Extraction

(Floor System)

The floor extraction is the most efficient kind of extraction, since the overspray has got its shortest way to the separating filters. Since foundation works or solutions with drive-in ramps aren‘t always possible, also an alternative to floor extraction proven in practice must be available.

Wall Extraction

(Wall System)

In combination with the flow ceiling TAD, WOLF offers a very efficient solution for an extraction above floor level. The air outlets of the flow ceiling are arranged acc. to our specifications so that there is a very strong flow profile to the extraction wall and the overspray is getting very fast to the extraction wall. For calculating the air outlets, flow measurements have been done by WOLF.

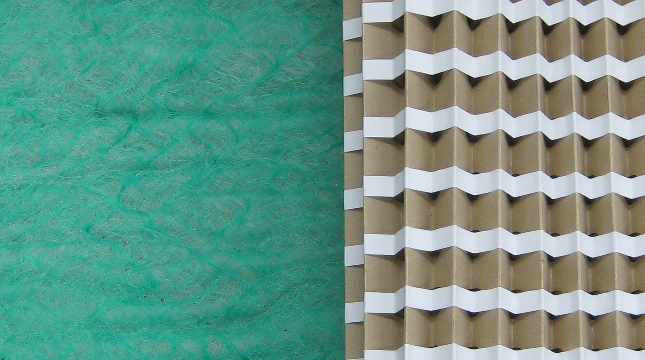

Separating Filters

These are integrated below grid level or in the extraction wall. In most cases, the approved glass fibre filters are installed. Since the paint consumption is not so high, usually a lifetime of at least one week is reached. Optionally, we offer a paper filter (folding cardboard filter) in combination with the glass fibre filter, reaching even longer lifetimes.

Lighting

An optimal lighting in the working range is indispensable for perfect surfaces. For a REPIT vision working bay, we are providing a luminous power of more than 1000 Lux. Ideally, the lighting at the REPIT working bay is designed just like in the spray booth, so that colour comparison and distinction as well as working in best light conditions are optimally given.

energy saving

(up to 70%)

LED-Lights

Already today, WOLF also offers LED-technology for the REPIT vision system. The higher investment costs for the LED-lights are balanced by following advantages:

high lifetime,

>30.000 working hours

no UV-radiation

comfortable light, no „flickering“

environmentally friendly

Machinery Technology

For product line REPIT vision, the complete machinery series of TAIFUNO®vision booths is available. Depending on the booth conception, a machinery is assigned to max. 4 working bays.

For a REPIT vision single bay solution, our newly developed smallest size is appropriate. Just like for the spray booth, also a heat recovery - optionally with VARIO©WRG - is indispensable.

Like for the TAIFUNO® booth, the Green Technology conception by WOLF (solarthermics, block heating power station, pellet heating) can be integrated without any problems.

One machinery is supplying up to four REPIT vision working bays.

Energy-optimized optionally with VARIO© WRG and GreenTechnology connection.