Bine Loader AN 70

for an even more precise and efficient harvest

Perfect Tear-off Technology

The new WOLF bine loader AN 70 is the generation following upon AN 60 which has already proved to be excellent. The nu-merous developments directly based on practice make it a real champion in its class.

Like its predecessor, the new AN 70 impresses by its enormous compatibility with the common tractor sizes on the market. Its low weight and sturdy, improved design assure a long and smooth operation.

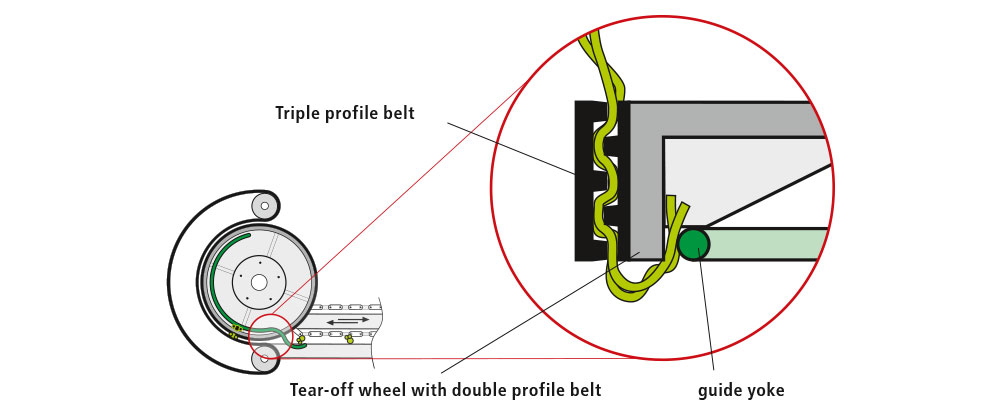

The cutting device has an especially long service life and guarantees a durable and precise operation. Modifications or mainte-nance work on the knife can easily be done in just a few steps. By the triple profile belt and deflection bow on the tear-off head, you can safely tear off even weaker and younger bines.

Propulsion of the bine loader is done by tractor hydraulics.

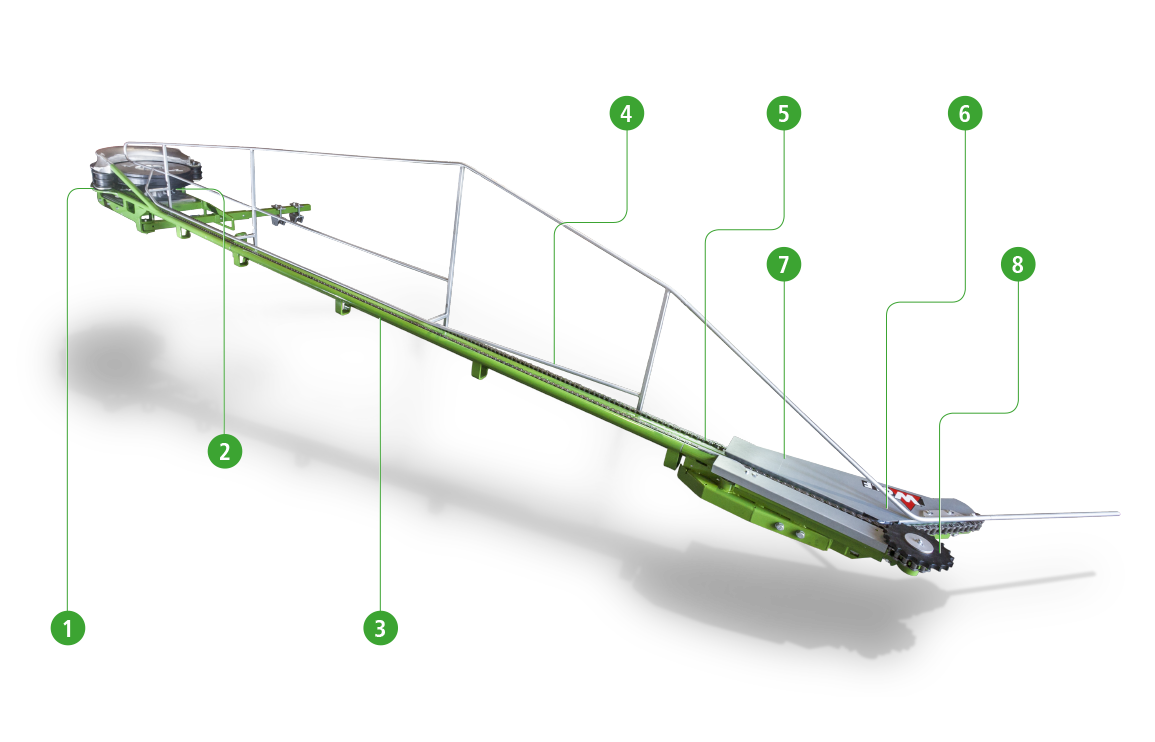

1 Starting protection on the deflection pulley

2 High-Grade Gearbox

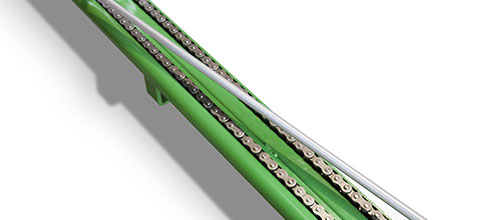

3 Glide bar in the shaft

4 Revised bine railing

5 Adjustable bine transfer

6 Additional deflection gear

7 Ergonomic cutting head

Bine Entrance

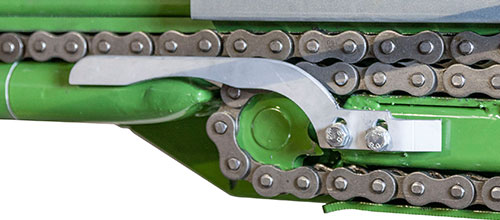

Double Chain Entrance

for even sequence, faster bine grabbing and entrance to the cutter.

The second chain makes the difference.

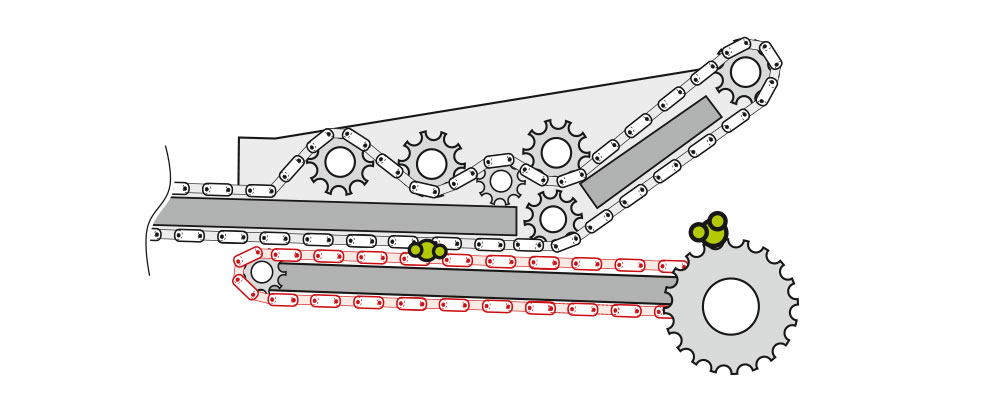

Tear-Off Head

Deflection Bow (optional)

The bine end is bent inwards by 180 degrees below the drum wheel for a safe grip.

– ideal for young and thin bines

– avoiding cloggingsrbeiten

Triple profile belt

for best tear-off results

Divisible

A further innovation is the separating point on the shaft. The AN 70 is the only device on the market which can easily be dismantled into two handy parts, if necessary. Now you are able to react more flexibly for transport or storage.