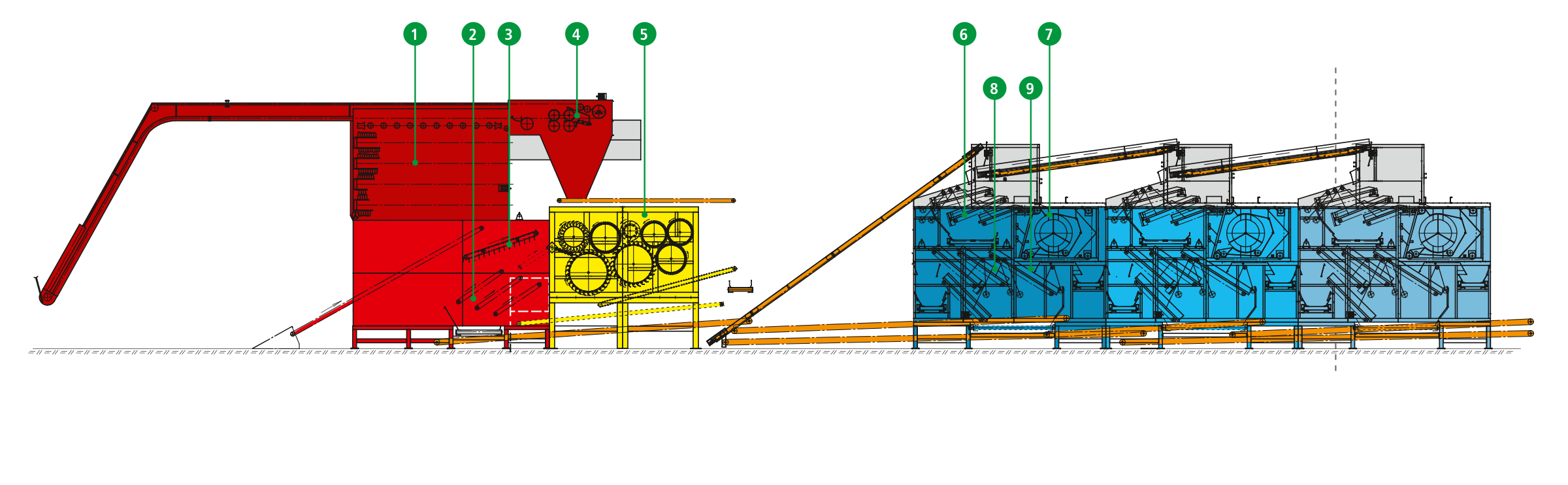

WSZ with STARPICKER© Picking Machine

reliable, highly efficient Harvesting Technology

High-performance Picking Machine

The WSZ is the most powerful hop-picking machine in our program.

Its modular construction enables an ideal adjustment to the hop grower’s requirements, providing a flexible installation. Its capacity can be increased later on at minimum expenditure. The WSZ picking machinery guarantees a first-class, gentle picking. By the working platform on three sides, you have a good access to the machine.

Adjustment and maintenance work can be done very comfortably. Picking drums distance, bine passage speed and picking drums rotational speed have a stepless control system.

The picking process can easily be adjusted to different hop varieties.

Advantages

- Modular construction

- First-class, gentle picking

- Maximal picking capacity

- Optimally developed components

- Quiet operation

- Adjustment and maintenance easy to be done

- Stepless control system

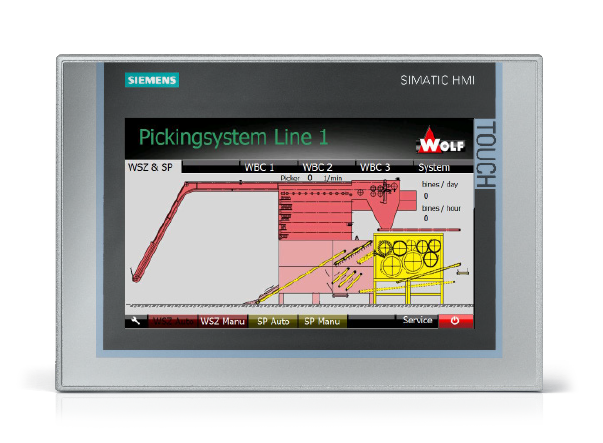

- Graphic Touch Control

1 Picking Drums

The cones are wiped off gently and without being damaged.

2 Triple Pre-Collection

3 Bypass

5 STARPICKER

The STARPICKER© is working maintenance-free during harvest. A twisting of bines or adhesion of waste material in the drums is almost excluded.

This self-cleaning effect has been achieved by a special cleaning unit. The pipe belt is filtering coarse waste out of the process.

6 Pre-Collection before Cleaning Fan

8 Pre-Collection before Rubber Belt Cleaning

After this pre-collection step, a total of 60% of the whole cone proportion from the hops are already led to the belt leading to the kiln.

Beside the positive effect on hop quality, the pre-collection is relieving the following cleaning belts and increasing their efficiency.

PICKER WSZ

Picking fingers with springs enable a careful intervention into the whole bine depth.

The cones are wiped off gently and without being damaged.

STARPICKER

The STARPICKER© is the most powerful subsequent picker unit by WOLF so far. Different, in speed and design optimized picking drums are separating the cones from the remaining material as fast as lightning.

The STARPICKER© is working maintenance-free during harvest. A twisting of bines or adhesion of waste material in the drums is almost excluded.

This self-cleaning effect has been achieved by a special cleaning unit. The pipe belt is filtering coarse waste out of the process.

WINDBELTCLEANER WBC

About 50% of the total cone proportion is already completely cleaned here and can be led as pure hops directly to the belt leading to the kiln. The pre-collection rubber belt is saving these clean cones from further process steps.

Touch-Display

By a clear Touch Display which is easy to handle, you can centrally control the whole WSZ 1000.

The mobile panel serves for adjustment on site, so that you can immediately check the result.