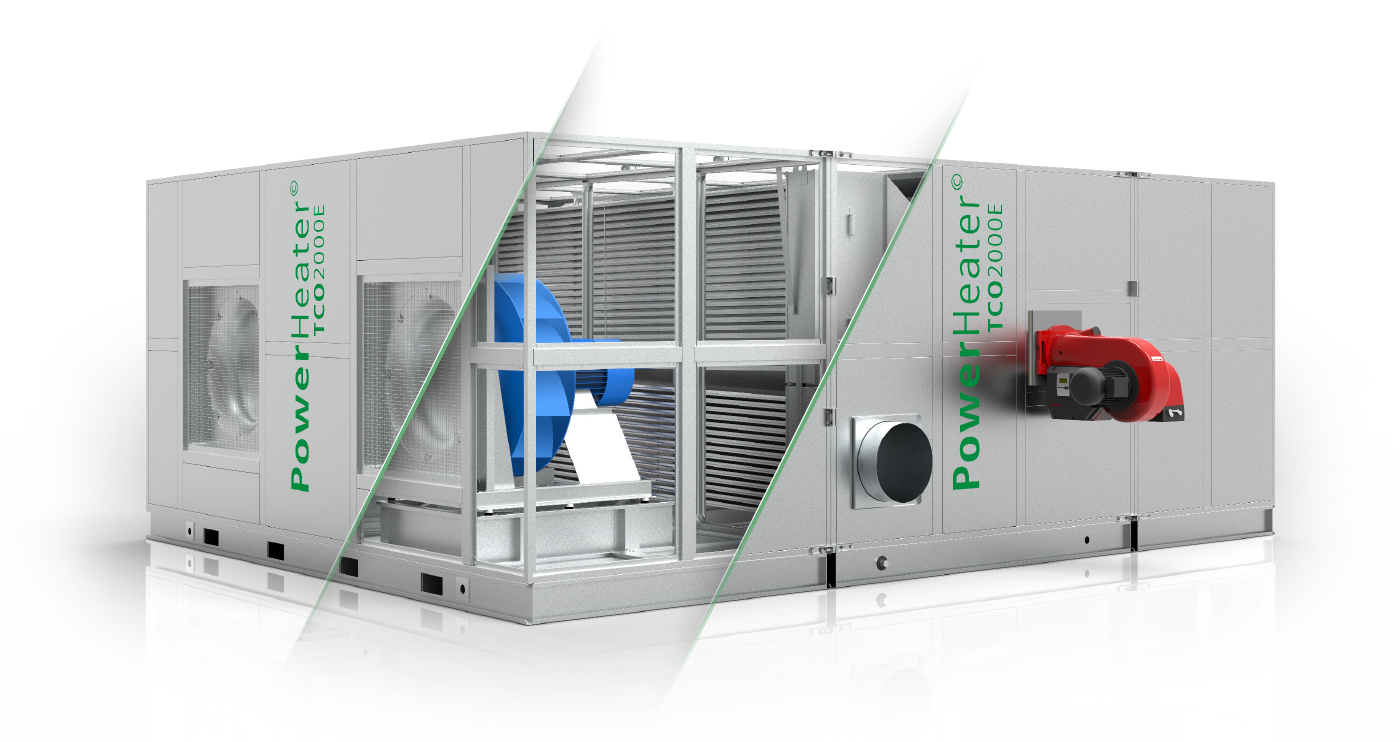

PowerHeater© TCO2000E Kiln

powerful - silent - energy-saving

Hop Drying at the highest level

The redesigned Power Heater enables a highly efficient hop drying together with resource-conserving operation.

The heart of the device is the combustion chamber. The challenge to be met is an optimal exploitation of the combustion space and the side areas. That’s exactly what is achieved by the cone-shaped body, assuring an even firing performance.

Fans of energy efficiency class IE3 with pressure stable freewheel and backward curved blades.

Heat Exchanger

Innovative top performance by flue gas counterflow technology

Modern Fan Technology

Freewheel fans with backward curved blades

Frequency converter

(FU)

Optimal, stepless speed regulation and gentle motor start

Customer-friendly Maintenance

Easy access to the heat exchanger, heating pockets without turbulators

The major innovations at a glance

Conical heating cavities; 2/3 to 1/3 flue gas case

The asynchronous tapering guarantees a constant flue gas velocity and highest energy efficiency

Embossed heating cavities

thus no turbulators necessary – assuring an uncomplicated maintenance

Air guidance in counterflow principle

The patented procedure guides the smoke flue forward through the oven, increasing efficiency considerably.

High-grade materials

The heat-resistant combustion chamber made of stainless steel incl. acid-proof flue gas case have got an efficiency of „92% plus“ and a much longer lifetime, enabling a modulating / condensating operation at lower exhaust gas temperatures.