WK-com THERMO

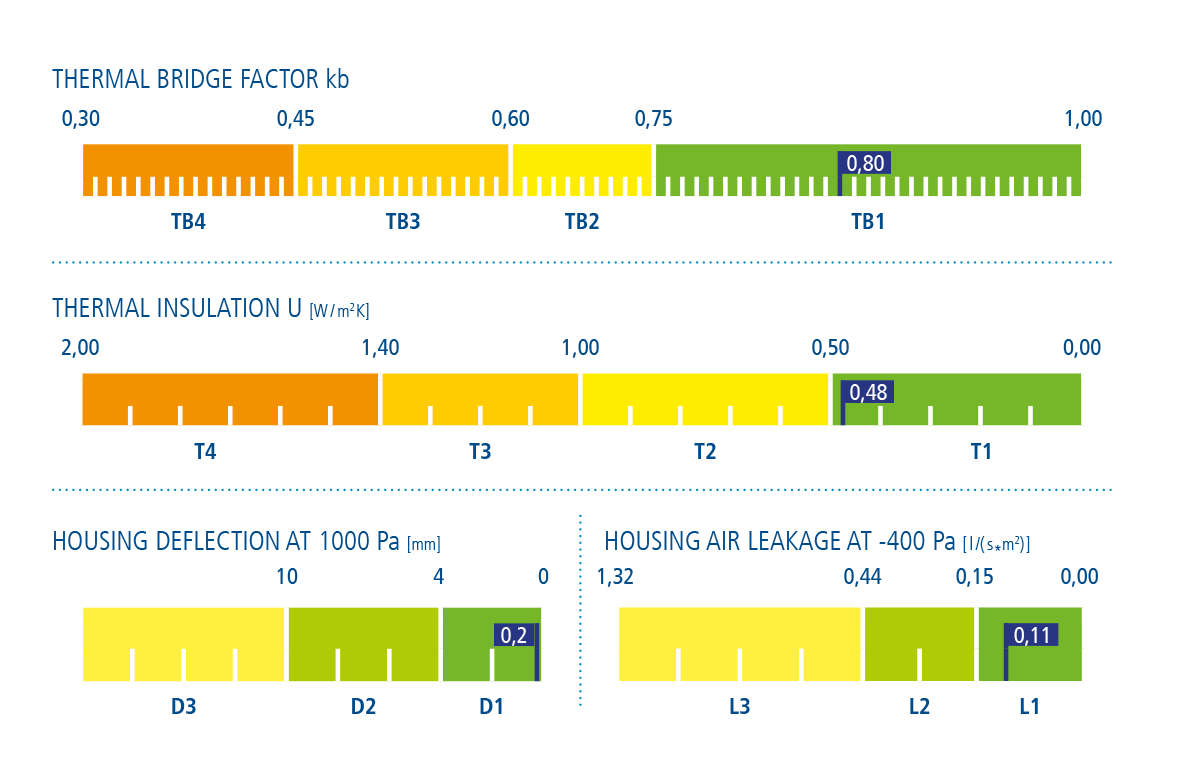

T1 / TB1 Performance in the standard version

Highest standard thanks tothermal bridge optimised design

Benefits

- Highest housing energy efficiency class T1/TB1, TÜV (German Association for Technical Inspection) certified

- Extremely flexible geometry, any dimension can be implemented

- Universally usable for all areas of application, V2A, V4A, AlMg3 or coated inner surfaces

- Hygienically smooth and wipeable, no indentations or dirt-collecting corners

- Can be fully dismantled, threaded and push-fit design

- No risk of penetration of moisture, condensate-free and vapour-proof

- For indoor or outdoor installation

- Corrosion-resistant

- Structural tight, tongue and groove construction with thermal panel

- Inherently stable and self-supporting framework design

- Lifting and positioning from above using screw-in crane eyes

- Unit modules easy to secure with screws from the inside for an airtight installation

Exceptional performance!

WK-com THERMO

The WK-com Thermo series unit in its standard design underwent TÜV SÜD (German Association

for Technical Inspection) testing acc. to EN 1886 and recorded an outstanding performance

in all test parameters.

The WK-com Thermo air handling unit is available both as an indoor unit and in a weatherproof design with air flow rates of up to 120,000 m3/h.

From the hygiene version (VDI 6022 / DIN 1946 T4) and swimming pool design right through to the economical standard solution – the WK-com Thermo covers all applications and complies with all current standards and guidelines.

This means that you can respond flexibly to any structural conditions knowing that the regulatory and energy efficiency aspects are covered.

Quality guarantee

The WK-com Thermo air handling unit complies with all hygiene, energy efficiency and structural standards and guidelines. The design meets the highest of requirements. Optimum maintenance and cleaning is ensured by the perfected series design.

Membership of the AHU manufacturers' association and EUROVENT with inspections by external institutions guarantee a high product and quality standard.

» Recognised seal of approval and certification from renowned institutes are a testament to the high quality and technical maturity of the WK-com unit series «

Test results

Mechanical and thermal values Wk-com THERMO

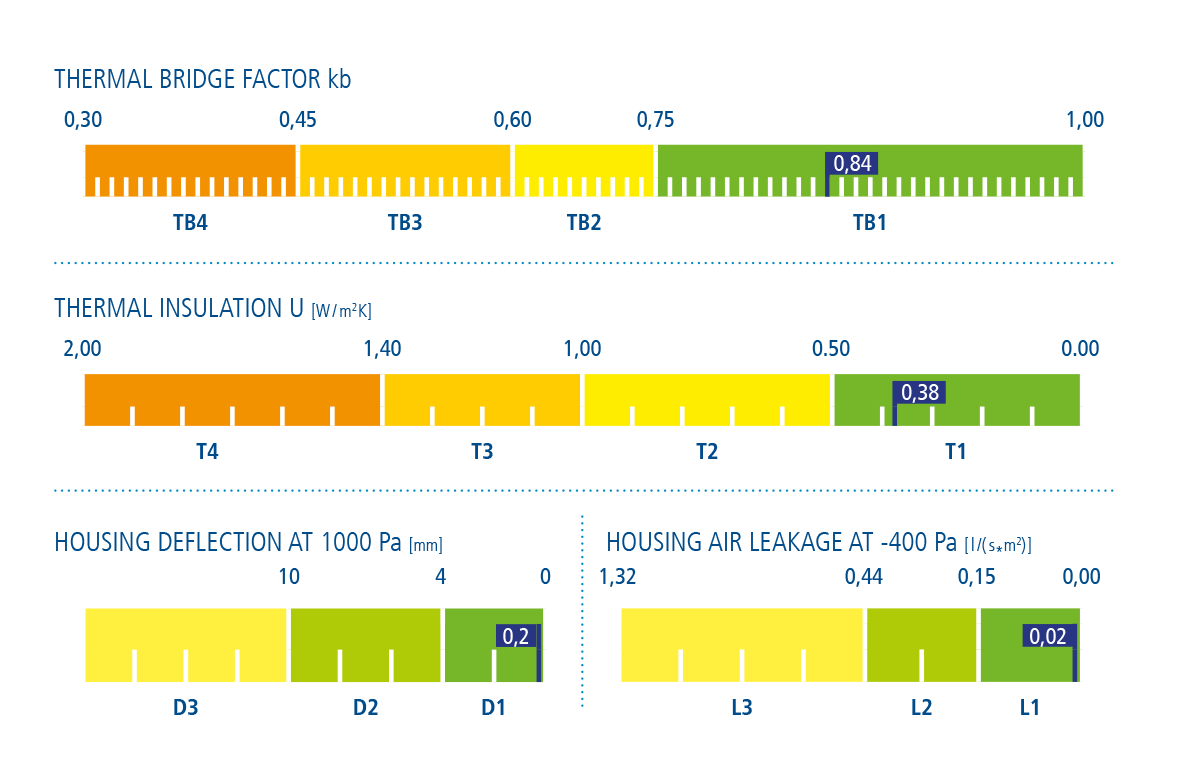

Mechanical and thermal values WK-com THERMO-PLUS

Sound

Extremely quiet

The double-shell design with three integral panel thicknesses ensures ideal separation of the outer and inner skins. Aside from excellent thermal values, this unique design also has an extremely positive impact on the acoustic properties. Resonances are attenuated optimally for whisper-quiet operation. The WK-com THERMO with thermal panels achieves insertion attenuation with a peak value of Σ 53.3 dB.

Insertion attenuation of the housing

Insertion attenuation of the housing WK-com THERMO-PLUS

» We take the problem of noise extremely seriously.

This is why our air handling units are among the quietest in the world! «

WK-com THERMO in detail

Maximum tightness

The attached and sealed door gaskets are located in the door frame. This creates a system with a high tightness level. The rounded corners ensure consistent laying of the sealing profile without gaps. Neither heat nor sound permeate to the outside.

Door closure system

The operating doors are equipped with coated, adjustable, maintenance-free hinges and have manual lever locks, which are located outside of the air stream. In the overpressure range, the housing door is secured by a catching device. Double lever locks can be used as an option. All locks can be supplied as lockable with locking cylinder.

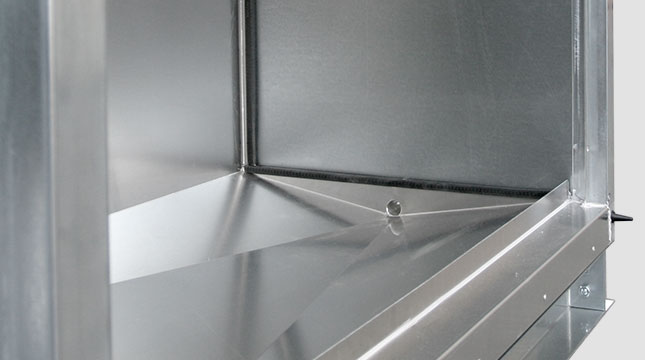

3D condensate pan

The 3D pan, made from aluminium or stainless steel, has a three-dimensional fall, which reliably prevents water residues and the associated hygiene risks arising from bacterial growth.

Clamping device

Outdoor units have clamping devices on the doors to prevent the wind accidentally closing them and to ensure easy and safe access.

WK-com THERMO-PLUS in Detail

The rock among the milestones

Our latest WK-com THERMO-PLUS has been developed based on our approved and tested double-planked, weatherproof WK-com THERMO series air handling unit.

Structural precision work has made it the perfect air handling unit for extreme applications thanks to its outstanding housing ratings.

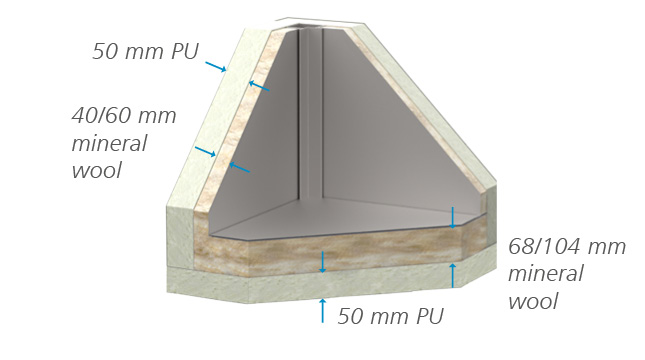

Boarded corners, thermally separated screw fitting

Advantages

- TÜV tested according to DIN EN 1886

- for indoor or outdoor installation

- double housing construction

- additionally decoupled door construction

- best thermal values T1 / TB1

- best mechanical values L1 / D1

- thermal bridge free

Values as tested acc. to DIN EN 1886

| Unit type Series | Insulating thickness | Insulating material | Housing leakage | Deflection | Filter bypass leakage | U | kb | Housing soundproofing | |||||||||

| [mm] | [mm] | + | - | + | - | + | - | + | - | 125 | 250 | 500 | 1k | 2k | 4k | 8k | |

| Kl | Kl | Kl | Kl | Kl | Kl | Kl | Kl | [dB] | |||||||||

| WK-com THERMO-PLUS |

82,5 | Mineral wool, 30 PU panels, 50 |

L1 | L1 | D1 | D1 | F9 | F9 | T1 | TB1 | 15,4 | 25,7 | 32,5 | 37 | 40,9 | 51,9 | 59,2 |

Filters

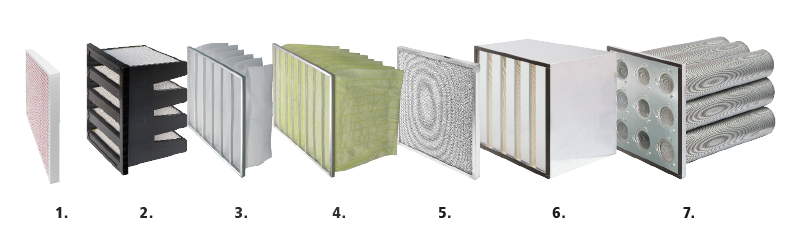

All WK-com units are fitted as standard with filters of filter classes ISO ePM10 > 50 % to ISO ePM1 > 80 % acc. to ISO 16890. Individual filters are also available on request (oil filter, grease filter, UV-C/ozone or activated carbon filter). The filters with optional treatment with biostatic preservative prevent the growth of fungi and bacteria. Biostatic filters boast an outstanding dust storage capacity and longer service life in damp conditions.

1. Panel filter 2. Compact filter 3. Short bag filter 4. Long bag filter 5. Grease filter 6. HEPA filter 7. Activated carbon filter 8. UV-C

Filter classes

ISO 16890 divides filters into groups. The filters are grouped according to separation efficiency with reference to PM1, PM2.5 and PM10 (0.3-10 µm particles), dust storage capacity, gravimetric separation efficiency and differential pressure.

Lowest filter bypass leakage F9 > applicable filter class ePM1 ≥ 80 %

With a peak value of < 0.1 % leakage, testing by TÜV-Süd confirms the perfected and design optimised solution of the filter insertion device.

Hygiene

The internal design is of the same highest hygiene standard in all series.

All WK-com units can be supplied in a hygiene design in accordance with VDI 6022-1, DIN 1946-4 and EN 13053.

» WOLF never compromises on hygiene «

Housing versions

INDOOR

design

Thanks to the thermal bridge optimised design, the unit series is ideal for any challenging application. The insulating PU thermal profiles (optional rock wool) are already coated as standard in RAL 7037. As an option, you can, of course, choose the RAL colour that suits your requirements.

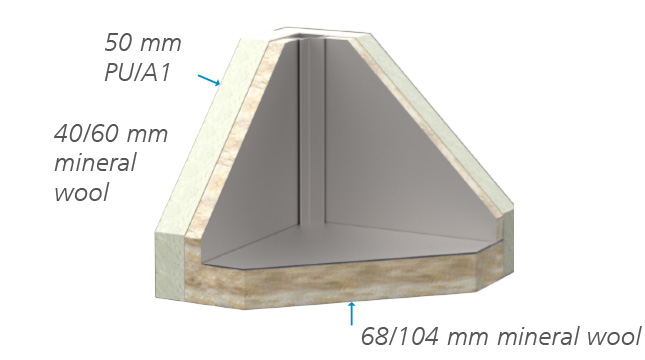

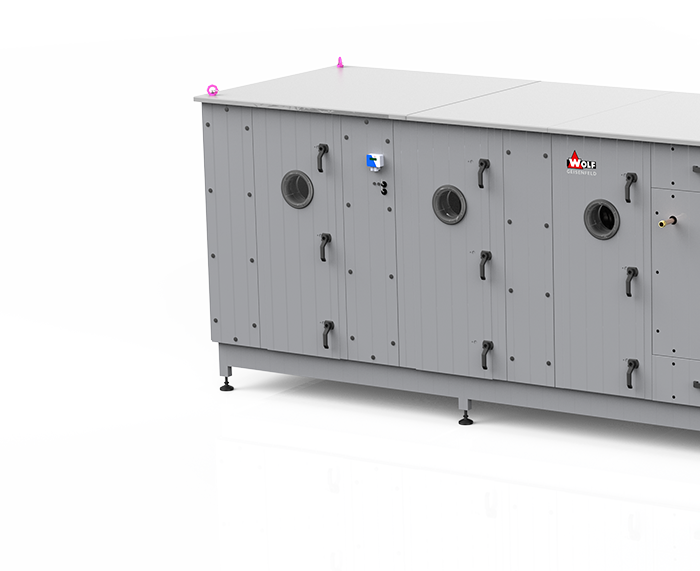

WK-com THERMO

The standard T1 / TB1 air handling unit for a wide range of challenging applications.

Numerous special and mixed sizes enable maximum flexibility for matching the unit to the relevant project requirements.

- Flow rate up to 120,000 m3/h

WK-com THERMO-PLUS

Thanks to the thermal bridge-free construction, it is designed for use to the highest requirements. All geometries can be implemented. The internal dimensions are the same for both THERMO and THERMO-PLUS versions.

- Flow rate up to 120.000 m3/h

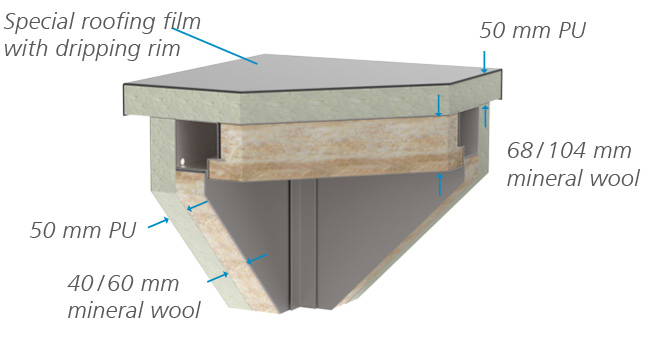

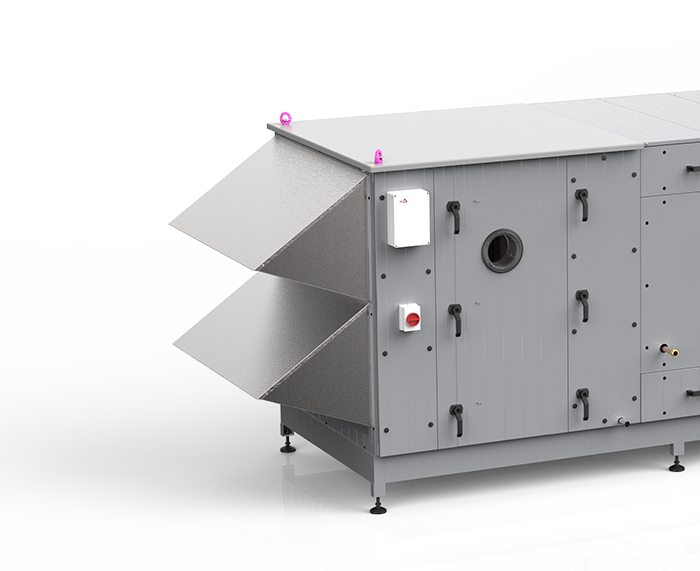

OUTDOOR

design

Thanks to the double-shell design, the unit series is ideal for outdoor installation. The insulating PU thermal profiles (optional rock wool) are already coated as standard in RAL 7037 and offer optimum

protection against corrosion. Of course, you also have the option to choose the RAL colour that suits your requirements. The roof with projecting roof panels is fully sealed with a special weatherproof and UV-resistant film and has a dripping rim. Weatherproof units are supplied on an all-round base frame. Optimum use outdoors is tested in accordance with EN ISO 13857.

WK-com THERMO OUTDOOR

Thanks to the double-shell design, the unit series is ideal for outdoor installation. The insulating PU thermal profiles (optional rock wool) are already coated as standard in RAL 7037 and offer optimum

protection against corrosion. Of course, you also have the option to choose the RAL colour that suits your requirements. The roof with projecting roof panels is fully sealed with a special weatherproof and UV-resistant film and has a dripping rim. Weatherproof units are supplied on an all-round base frame. Optimum use outdoors is tested in accordance with EN ISO 13857.

WK-com THERMO-PLUS OUTDOOR

Outdoors too, thanks to the thermal bridge-free construction, numerous individual requirements can be met. All geometries can be implemented. The internal dimensions are the same for both THERMO and Thermo-PLUS versions.

- Flow rate up to 120.000 m3/h

Best performance in standard version

Inherently stable housing in modular design for crane unloading using screw-in transport lugs in the housing corners. The housing is smooth on the inside in accordance with VDI 6022 to ensure a perfect level of hygiene. The unit floor is designed without indentations for wiping clean. All housing surfaces are smooth on the inside, hygienically sealed with tested, microbially inert sealants in accordance with VDI 6022.

All housing components are corrosion-resistant, and the overall structure has no welds, rivets or cut edges. The housing can be fully dismantled and recycled in an environmentally responsible manner.

The unit modules are screwed together from the inside, making them airtight and easy to assemble. The units are inherently stable and can be transported and set up without a base frame. All unit modules can be lifted and positioned from above using the crane eyes.

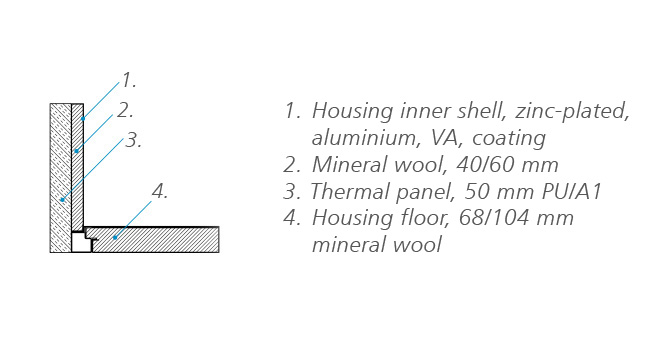

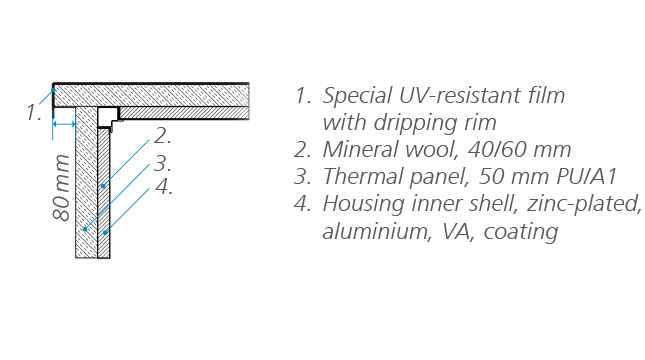

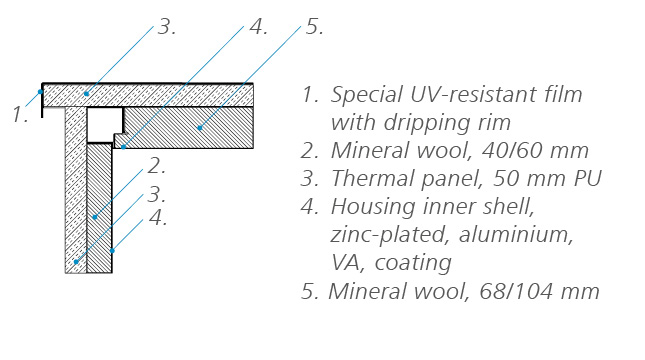

The self-supporting framework consists of hot-dip galvanised, enclosed special pipe profiles that are screwed to an inherently stable frame unit with die-cast aluminium corner connectors. Mechanical stability in accordance with testing by TÜV Süd to EN 1886 (M): D1 Wall and ceiling mounted design comprising a triple skin system with three integral panels, which are separated by insulation of fire class A2 s1d0 on the inside and B1 on the outside. The cladding thickness is 80/110 mm. The inner cladding is made of 1.0 or 1.5 mm thick hot-dip galvanised sheet steel, optionally aluminium, stainless steel or with a coating.

The self-supporting and inherently stable framework is enclosed by the outer cladding with tongue and groove system, made of strip-coated hot-dip galvanised sheet steel in RAL 7037 (different RAL colours available to choose from), for a permanently airtight and weatherproof enclosed installation. Floor in double skin design with a panel thickness of 68/104 mm and inserted insulation made of mineral wool, non-flammable (A2 s1d0) acc. to EN 13501. Unit floor wipeable and walkable.

This design eliminates any risk of penetration of moisture or thermal bridges. All frame parts are arranged on the inside and are fully enclosed by the outer panels. High grade thermal insulation achieves housing class T1 (heat transition coefficient U: (0.48 W/m2K) for heat losses via the housing and housing class TB 1 (thermal bridge factor: 0.83) for thermal bridges of the housing.

The overall structure also ensures optimum airtightness of the housing, tightness class L1. All values are type-tested and have been verified by means of TÜV Süd testing to EN 1886.

The operating doors in the housing design are equipped with chrome plated, adjustable, maintenance-free hinges, and can be fitted with manual lever locks as single lever or double lever locks, with optional disable. In the overpressure range, the housing door is secured by an integral safety catch in the lever lock. Inspection covers have clamps and handles on the outside. Inspection doors and covers are sealed with tested special microbially inert, closed-pore sealing profiles.

Moisture-sensitive structural components are made from a corrosion-resistant material and have an insulated and completely drainable 3D aluminium or stainless steel pan. The 3D pan has a three-dimensional fall, which reliably prevents water residues and the associated hygiene risks from bacterial growth.

All functional units are easily accessible on both sides for inspection and maintenance purposes or extensible up to a unit clearance height of 1.6 m. The inner surfaces are completely smooth without any cut edges. All joints and grooves in the unit have been sealed to ensure that they are disinfectant-proof and can be cleaned without any residue. Fan, filter and dehumidifier parts have double wall sight-glasses as standard from a unit clearance height of 1.30 m, as well as humidifier parts at a unit height upwards of 0.8 m. All components are factory-cleaned in line with the applicable hygiene standard and packaged in film.

In the weatherproof design, roof panels are also fitted so that they protrude 80 mm all round. Roof sealing with affixed 2.8 mm thick, special UV-resistant, airtight and watertight film with dripping rim all around. All unit separation points, roof openings and threaded holes for crane eyes are permanently sealed with special UV-resistant roofing film to ensure that they are airtight and watertight. All mounted parts have additional UV and weather protection.